Essential Device: Understanding the Functionality and Importance of the 2-Way Stopcock

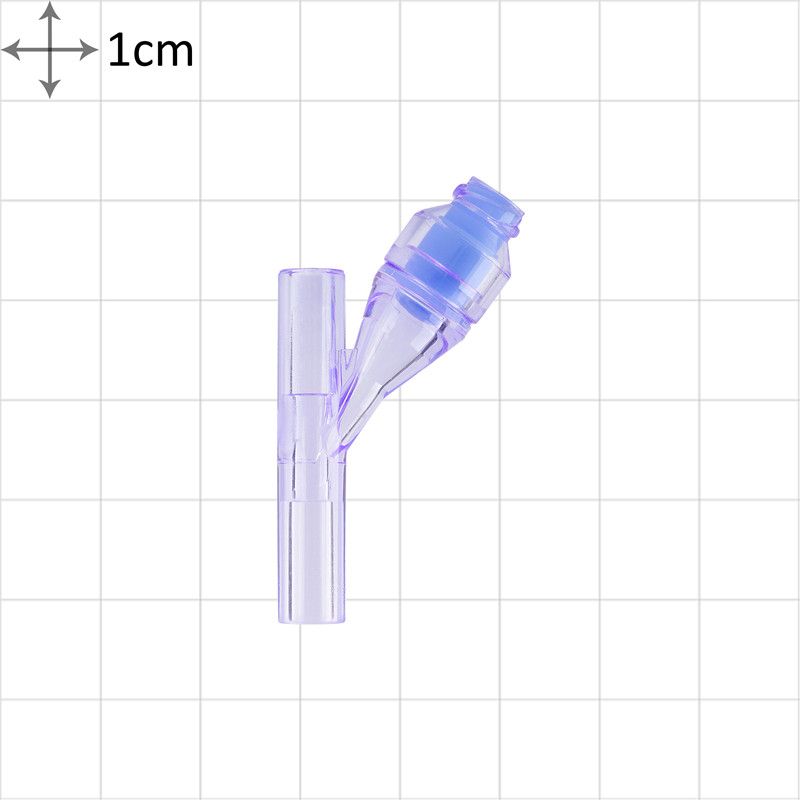

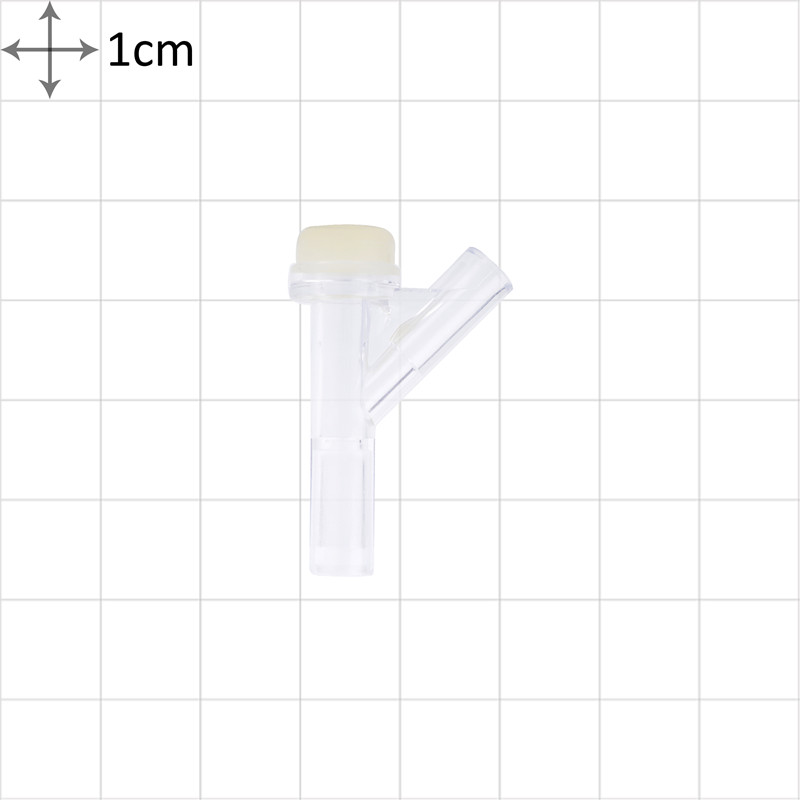

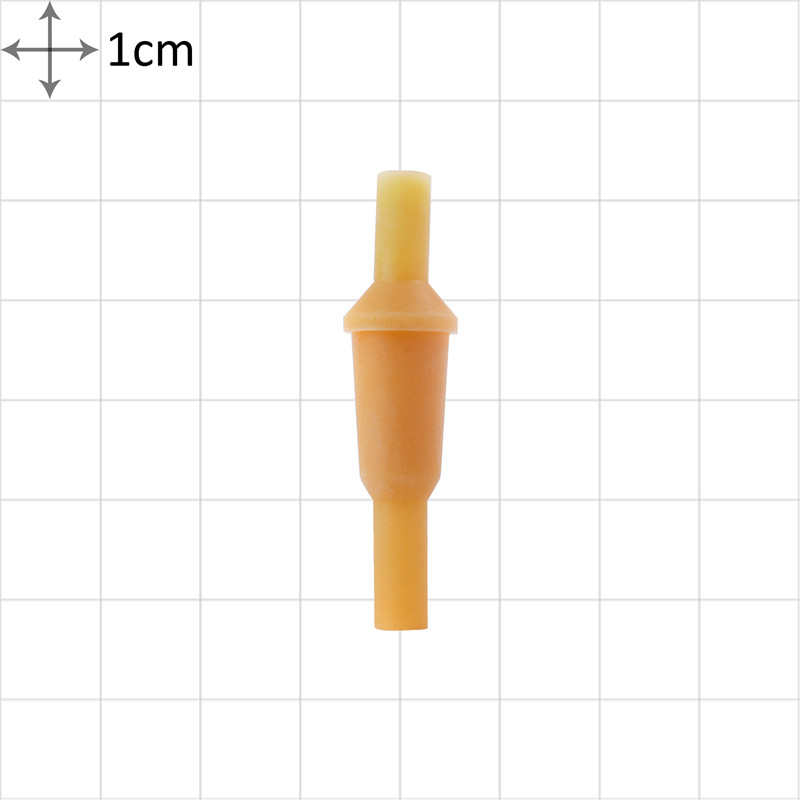

Title: Revolutionizing Medical Instrumentation with the 2-Way StopcockIntroduction:Innovation lies at the heart of the medical industry, constantly revolutionizing healthcare practices and improving patient outcomes. Among these groundbreaking advancements is the development of the 2-Way Stopcock, an essential medical instrument used by healthcare professionals to administer fluids and medications. In this article, we delve into the multifaceted nature of this device, its crucial role in medical settings, and the company leading the charge in its manufacturing.I. The Significance of the 2-Way Stopcock:The 2-Way Stopcock, a vital component in intravenous therapy and other medical procedures, plays a pivotal role in delivering fluids and medications to patients. This versatile valve allows for precise control over the flow of liquids, ensuring accurate dosing and minimizing the risk of complications. It has become an indispensable tool in healthcare facilities globally, saving countless lives and enhancing patient care.II. The Anatomy of an Efficient 2-Way Stopcock:A typical 2-Way Stopcock consists of a cylindrical body connected to three ports, allowing for the attachment of syringes, infusion sets, or other medical devices. The rotating handle facilitates the adjustment of fluid flow, directing it to the desired route. The transparent casing allows for quick visualization of the fluid pathway, reducing the chances of error during administration. The device's compact design ensures easy handling, even in high-stress medical situations.III. Multiple Applications in Healthcare:The 2-Way Stopcock finds application in a wide array of medical procedures. In sterile environments such as operating theaters, it serves as a connection between different medical devices facilitating the administration of medications, blood products, or intravenous fluids, all while maintaining an aseptic environment. It also enables simultaneous infusion of multiple medications, saving time and reducing the risk of contamination.IV. Promoting Patient Safety:Patient safety is paramount in healthcare settings, and the 2-Way Stopcock aids significantly in this regard. By allowing healthcare professionals to regulate the flow of fluids with precision, the device minimizes the risk of medication errors and associated health complications. Its transparent body provides visibility that facilitates the identification and elimination of air bubbles, further enhancing patient safety during infusion.V. The Leading Manufacturer:At the forefront of manufacturing superior 2-Way Stopcocks is {}. With a long-standing commitment to advancing medical instrumentation, the company has been revolutionizing the industry dynamics. Their innovative product range combines cutting-edge technology, meticulous quality control, and a focus on patient well-being. With a passion for excellence, they continue to provide healthcare professionals with reliable, efficient, and user-friendly devices.VI. Quality Standards and Regulatory Compliance:The {} manufacturing process adheres strictly to international quality standards and regulatory requirements. Through rigorous inspections, meticulous quality control measures, and adherence to ISO standards, the company ensures that every 2-Way Stopcock leaving their facilities meets the highest quality benchmarks. This dedication to quality provides healthcare professionals with the confidence they require to deliver optimal patient care.VII. Innovation and Future Developments:Embracing the spirit of innovation, {} is constantly investing in research and development to improve its 2-Way Stopcock design and functionality. By collabo

Read More

Discover the Benefits of Luer Fitting Syringes for Medical Applications

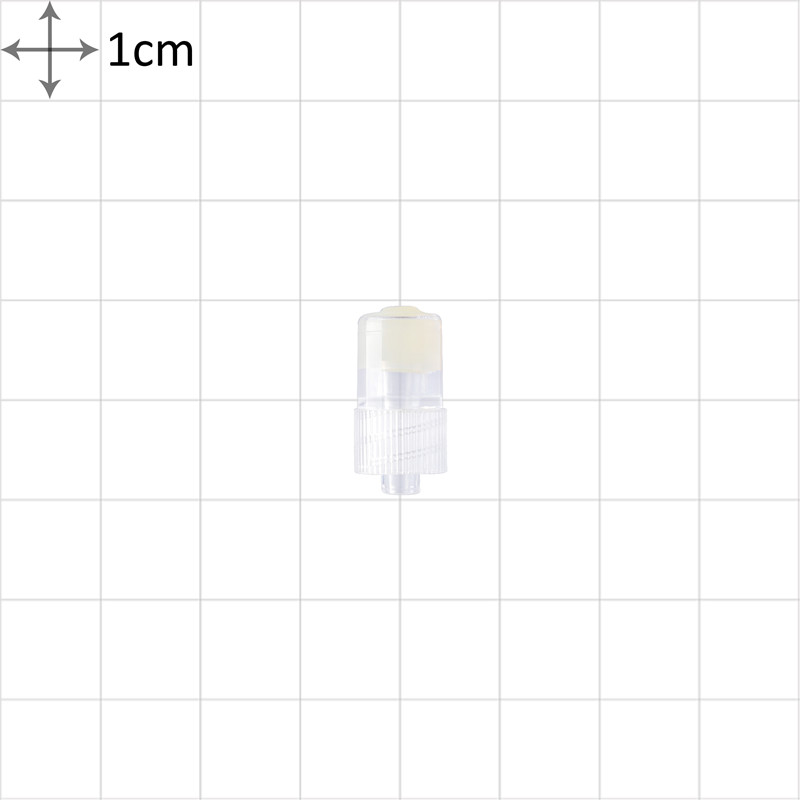

Title: Innovative Luer Fitting Syringe Revolutionizes Medical IndustryIntroduction:In a technological breakthrough, a pioneering syringe has been introduced that is set to transform the medical industry. This revolutionary syringe, equipped with superior Luer fittings, promises improved precision, safety, and ease-of-use. With its potential to raise the bar in medical procedures across the board, medical professionals are eagerly awaiting its widespread adoption.Innovative Features:The Luer Fitting Syringe is designed to cater to the diverse needs of medical practitioners worldwide. With an emphasis on precision, it offers a variety of innovative features that enhance the user experience while prioritizing patient safety.Firstly, the syringe incorporates a secure Luer-lock fitting mechanism, ensuring a tight, leak-proof connection between the device and other medical components. This robust design eliminates the risk of leakage during critical medical procedures, minimizing the potential for contamination and improving the overall safety of treatments.Secondly, the Luer Fitting Syringe boasts advanced graduations and markings, allowing healthcare professionals to accurately measure and dispense medication without any ambiguity. The precise measurement capabilities of this syringe significantly decrease the chances of medication errors, providing practitioners with the confidence necessary to administer treatments accurately and efficiently.Additionally, the syringe's ergonomic design guarantees ease-of-use for medical personnel. The Luer fittings ensure swift and straightforward connections, simplifying the overall injection process and reducing the risk of accidental needlestick injuries. As a result, healthcare professionals will have increased efficiency and improved outcomes while minimizing the potential for cross-contamination.Company Overview:{}, the leading manufacturer behind this groundbreaking development, has established itself as a pioneer in the medical equipment industry. With a focus on innovative solutions and extensive research and development capabilities, they have consistently provided cutting-edge medical devices to healthcare professionals globally.The company's commitment to quality is reflected in its state-of-the-art manufacturing facilities, which adhere to strict quality control measures and international standards. Through a combination of advanced machinery and skilled craftsmanship, they ensure that each product meets rigorous specifications, warranting reliability and effectiveness.Moreover, {} recognizes the importance of sustainable practices in the medical industry. Environmental responsibility is a core principle integrated into their manufacturing processes. By utilizing eco-friendly materials and reducing waste and energy consumption, they strive to minimize their ecological footprint while continuing to produce high-quality medical devices.Looking towards the Future:The Luer Fitting Syringe marks a significant advancement in medical technology, promising to improve patient safety, streamline medical procedures, and enhance healthcare practitioners' overall efficiency. With its user-friendly design and precise measurement capabilities, it is poised to revolutionize the medical industry.As healthcare professionals witness the myriad benefits this syringe brings, it is expected to gain swift and widespread popularity. Its potential to reduce medication errors and prevent cross-contamination will play a crucial role in elevating patient care standards.With {} at the helm of this groundbreaking innovation, the medical industry can anticipate a renewed focus on precision, safety, and ease-of-use in medical devices. The Luer Fitting Syringe is undoubtedly a game-changer, destined to improve clinical outcomes and reinforce the company's position as a leading provider of cutting-edge medical solutions.In conclusion, the Luer Fitting Syringe, developed by {}, is set to become a trailblazer in the medical field with its innovative features, advanced graduations, and ergonomic design. The union of precision and safety in one syringe has the potential to revolutionize medical procedures and significantly enhance patient care.

Read More

Seamless Tube Connection: Discover the Latest Advancements in Tubing Technology

Tube-To-Tube Connection Revolutionizes Industries: A Game-Changer in ConnectivityIn an era where technological advancements are fast-paced, companies are continuously striving to innovate and improve existing systems. One such groundbreaking development is the tube-to-tube connection, a cutting-edge solution that is revolutionizing multiple industries.Tube-to-tube connection, also known as 'ConnectorX,' is a disruptive technology developed by an industry-leading manufacturer specializing in connecting systems. It offers a reliable, efficient, and user-friendly alternative to traditional connectivity methods. By eliminating the need for bulky and complex connectors, ConnectorX simplifies processes and ensures seamless connections in various applications.Unlike conventional connectors that require multiple components, intricate installations, and meticulous alignment, the tube-to-tube connection offers a streamlined approach. Its simplicity lies in its design: two tubes seamlessly merge together through a secure locking mechanism, providing a robust connection without compromising efficiency or quality.The versatility of tube-to-tube connection finds its applications across several industries. In the automotive sector, it offers a game-changing solution for fuel lines, coolant systems, and air conditioning connections. With its robust construction and resistance to high temperatures and pressure, ConnectorX ensures the safety and reliability of critical automotive systems.Moreover, this innovative connector has also found a powerful application in the medical field. By eliminating the risks associated with conventional connectors, such as leaks and contamination, it enhances patient safety and accelerates medical procedures. From blood transfusions to intravenous therapy, tube-to-tube connection technology is a game-changer that helps medical professionals deliver precise and efficient care.The industrial sector has also witnessed the immense benefits of tube-to-tube connection. Manufacturers often rely on complex and costly systems for conveying fluids and gases; however, with ConnectorX, there is no longer a need for specialized connectors and extensive maintenance. This groundbreaking technology simplifies processes, reduces downtime, and ultimately leads to increased productivity.Furthermore, tube-to-tube connection is making waves in the aerospace industry by transforming critical systems. Whether in fuel lines or hydraulic systems, this innovation allows for secure and efficient connections. The lightweight design of ConnectorX also contributes to fuel efficiency for aircraft, ensuring a greener and more sustainable future.Additionally, the oil and gas industry heavily relies on connectors for transportation and extraction purposes. Tube-to-tube connection technology ensures safe and efficient operation in these demanding environments. Its resistance to corrosion, vibration, and extreme temperatures make it an ideal solution for offshore applications, where reliability is paramount.The company behind this revolution, which we will refer to as 'ConnectTech' (pseudonym), has been a pioneer in the field of connectivity solutions for over three decades. With a strong focus on research and development, ConnectTech has earned a reputation for delivering high-quality products that meet the evolving needs of various industries.ConnectTech's commitment to innovation has resulted in several patents, ensuring its exclusivity in tube-to-tube connection technology. The company's state-of-the-art manufacturing facilities adhere to rigorous quality standards, ensuring optimum performance and reliability in every ConnectorX unit produced.Moreover, ConnectTech provides comprehensive customer support, with highly skilled engineers and technicians assisting clients in integrating this cutting-edge technology into their existing systems. The company's unwavering dedication to customer satisfaction has earned it a loyal clientele, spanning across diverse sectors and geographies.Looking towards the future, ConnectTech envisions a broadening of applications for the tube-to-tube connection technology. From renewable energy systems to underwater exploration, the potential uses are limited only by imagination. ConnectTech's commitment to continuous improvement ensures that this revolutionary connectivity solution will remain at the forefront of industry advancements.In conclusion, tube-to-tube connection, represented by ConnectTech's ConnectorX, is transforming industries by offering a simpler, more reliable, and efficient connectivity solution. Its applications span across automotive, medical, industrial, aerospace, oil, and gas sectors, providing countless advantages to businesses. ConnectTech's expertise and dedication to innovation have positioned it as a leader in this groundbreaking technology, with a vision of pushing the boundaries of connectivity even further.

Read More

20mm Vial Adapter: Everything You Need to Know

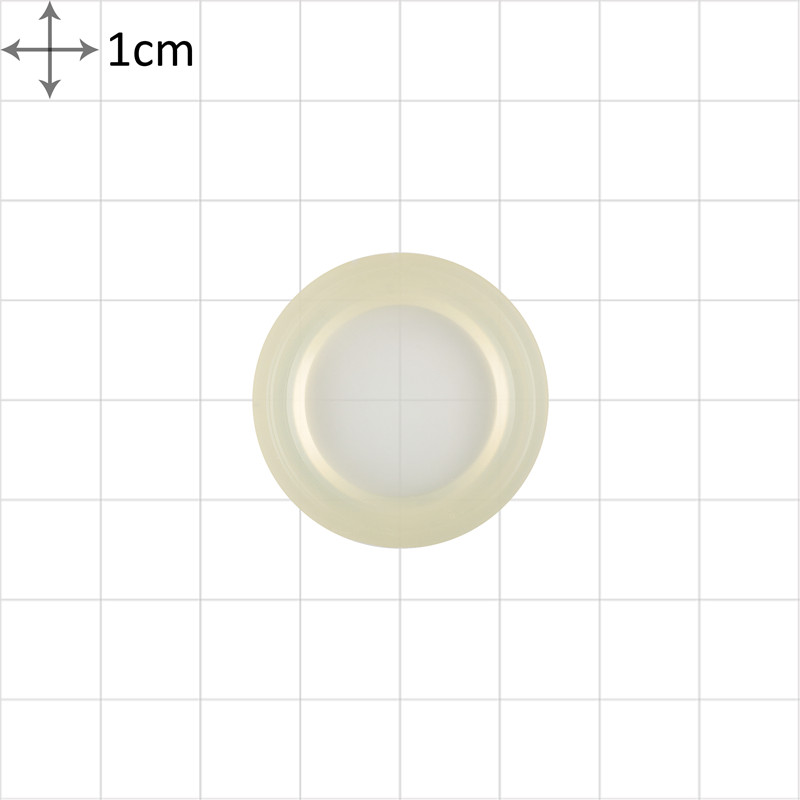

We are excited to announce the launch of our innovative Vial Adapter 20mm, a groundbreaking solution that will revolutionize the pharmaceutical industry. This new product has been designed to meet the growing demand for safe and efficient vial access, and we are confident that it will provide significant benefits to both healthcare professionals and patients.Our company has been a leading provider of pharmaceutical packaging solutions for over 20 years. We have a strong track record of developing high-quality products that meet the evolving needs of the industry. Our team of experts is dedicated to pushing the boundaries of innovation and creating solutions that deliver real value to our customers. With the introduction of Vial Adapter 20mm, we continue to demonstrate our commitment to driving positive change in the healthcare sector.Vial Adapter 20mm is a game-changer in vial access technology. It has been specifically designed to offer a safe and reliable method for accessing medication from vials. The product features a unique design that ensures a secure connection to the vial, preventing any potential leaks or contamination. This is crucial in maintaining the integrity of the medication and ensuring the safety of patients.One of the key advantages of Vial Adapter 20mm is its compatibility with a wide range of vials, making it a versatile solution for pharmaceutical companies. This flexibility allows for seamless integration into existing manufacturing processes, minimizing the need for costly equipment changes. Furthermore, the product is available in both sterile and non-sterile options, catering to the diverse requirements of the industry.In addition to its superior functionality, Vial Adapter 20mm is also designed with user convenience in mind. The product is easy to handle and can be swiftly attached to vials, saving valuable time for healthcare professionals. This is particularly beneficial in clinical settings where efficiency is paramount. By streamlining the vial access process, Vial Adapter 20mm contributes to improved workflow and enhanced productivity.Furthermore, our company is committed to sustainability, and Vial Adapter 20mm reflects this dedication. The product is manufactured using high-quality, eco-friendly materials, minimizing its environmental impact. We believe that sustainability should be at the core of all our operations, and Vial Adapter 20mm exemplifies our ongoing efforts to reduce our ecological footprint.With the launch of Vial Adapter 20mm, we are confident that we are introducing a product that will significantly enhance the pharmaceutical packaging landscape. We have already received positive feedback from industry professionals who have praised the product for its exceptional performance and user-friendly design. As we continue to roll out Vial Adapter 20mm to the market, we are excited to see the positive impact it will have on the industry as a whole.In conclusion, the introduction of Vial Adapter 20mm represents a significant milestone for our company and the pharmaceutical packaging sector. We are proud to offer a product that combines cutting-edge technology, user convenience, and environmental sustainability. With Vial Adapter 20mm, we are once again demonstrating our commitment to driving positive change and delivering value to our customers. We are confident that this innovative solution will set new standards for vial access and make a meaningful difference in the healthcare industry.

Read More

Innovative Needle-Free Injection Technology: A Gamechanger in Vaccine Administration

Needleless Injection Site to Modernize Drug Delivery for Patients GloballyNeedleless Injection Site, a revolutionary drug delivery system, is set to change the way patients receive their medications. The innovative technology, developed by a California-based pharmaceutical equipment company, will offer an alternative to traditional needle injections. With Needleless Injection Site, patients will no longer need to endure the pain and discomfort associated with injections."We are excited to introduce this state-of-the-art technology that will revolutionize drug delivery for patients globally," stated a spokesperson for the pharmaceutical equipment company.Needleless Injection Site technology works by using a small, high-pressure burst of medication to penetrate the skin's surface, leaving no needle mark. The system is designed to provide a unique and effective method of drug delivery for various medical conditions, including diabetes, arthritis, and multiple sclerosis."We believe that the Needleless Injection Site will be a game-changer in the medical industry, providing patients with a more comfortable, efficient, and reliable way of receiving their medication," said the spokesperson.Unlike traditional needles, Needleless Injection Site is designed to be simple to use, making it ideal for patients who prefer self-administration. Patients can control the dosage and frequency of medication delivered and avoid the need for needles, reducing anxiety around needle phobia.Furthermore, the Needleless Injection Site system is cost-effective for both healthcare providers and patients. The potential health risks associated with traditional needle injections, such as the spread of bloodborne diseases and infections, will be minimized, along with the accumulation of needle waste, reducing the impact on the environment.The company is committed to ensuring that Needleless Injection Site technology is widely available to patients who need it. The pharmaceutical equipment company is currently in talks with healthcare providers, insurance companies, and government bodies globally to make the system widely accessible. The system has already received regulatory approvals from the US Food and Drug Administration (FDA), the European Medicines Agency (EMA), and Health Canada.The company is currently developing a range of Needleless Injection Site delivery systems to cater to the diverse needs of patients. The systems will include multi-dose, single-use, and reusable devices. The aim is to provide more options for patients and healthcare providers, enhancing the patient experience further.Several clinical trials of the Needleless Injection Site system have shown positive results, with patients reporting significant improvement in medication administration efficiency and considerably reduced discomfort and pain. The pharmaceutical equipment company intends to continue testing and refining the system to ensure the utmost patient convenience and safety.The Needleless Injection Site technology has the potential to revolutionize drug delivery for millions of patients worldwide. With its innovative design, simplicity of use, and cost-effectiveness, it has the potential to improve the quality of care for a wide range of conditions."Through the development of Needleless Injection Site, we are proud to contribute to the advancement of the medical industry, offering patients a more comfortable, efficient, and sustainable way of receiving their medication," said the spokesperson.The company has also expressed its commitment to transparency in conducting business and partnering with healthcare providers to improve healthcare services.The Needleless Injection Site is set to be the future of drug delivery, providing patients with a safer, more comfortable, and eco-friendly option for getting the treatment they need.

Read More

Quality Tubing and Connectors for All Your Industrial Needs" becomes "Reliable Tubing and Connectors to Meet Your Industrial Demands

Tubing and Connectors: A New Era of Innovative TechnologyTubing and connectors have long been an important and vital component of many industries, including medical and semiconductor companies, automotive and aerospace manufacturers, and many more. The development of new materials and processes in the manufacturing of tubing and connectors have provided significant improvements in performance and efficiency, leading to ever-increasing uses in various applications. This has opened doors to many new possibilities, and one such Tubing and Connector company is {}.Introduction to the Company {}{}(requires the removal of the name), founded in 1960, is a global leader in tubing and connector manufacturing. The company has a diversified portfolio that includes custom extrusion, molded components, and fabricated tubing assemblies. The company has a global reach, supplying to various industries, including medical technology, aerospace, automotive, and semiconductor industries, to name a few.{}'s products are designed and manufactured with the highest industry standards to ensure that they meet the exacting requirements of customers. The company has a reputation for excellence in product development and customer service.{} Product Lines{}'s product line includes a range of tubing and connectors for various applications.1. Medical Tubing and Connectors{} manufactures custom tubing and connectors used in medical devices like heart valves, catheters, and drug delivery systems. The company uses a wide range of materials, including silicone, urethane, PVC and other materials, to create products specific to the needs of clients.2. Aerospace Tubing and ConnectorsAs the aerospace industry continually evolves, so do the requirements of its tubing and connector needs. {} fabricates parts and assemblies to support various aspects of aerospace applications. Aerospace assemblies require high-quality and high-precision components, such as connectors and tubes that can pass strict requirements, making {} the go-to manufacturer of aerospace tubing and connectors.3. Automotive Tubing and ConnectorsAutomotive manufacturers require heavy-duty tubing and connectors that can withstand harsh conditions. {} creates tubing and connectors used in various automotive applications, such as fuel lines, air conditioning lines, brake lines, and others. The tubing and connectors are custom made with materials that can withstand the heat, pressure, and vibration found in vehicles.4. Semiconductor Tubing and ConnectorsSemiconductor companies require high-quality tubing and connectors to operate their equipment. {} manufactures and delivers high-precision, cleanroom tubing and connectors used to maintain a clean environment in manufacturing. The company uses advanced technology and materials to meet strict standards and have provided manufacturers in the semiconductor industry with top-of-the-line products used in equipment such as chip makers.New Developments{} is always innovating and expanding their product lines to meet the evolving needs of their clients. The company has been developing new technologies and materials to enhance its products' performance, durability, and reliability. Recently, the company announced its newest development in high-performance tubing.Developments include metallic and plastic materials that can withstand extreme conditions found in harsh environments such as high pressure and temperatures, corrosive elements, and physical stress. These improvements will impact various industries that require custom tubing and connectors.The Future of Tubing and ConnectorsTubing and connectors have become an essential component of many modern industries. The integration of technology and the emergence of new materials have prompted innovative research and development, improving efficiency and reliability. {} has demonstrated its ability to provide customers with high-quality products and customer service that exceed their expectations. They are committed to producing state-of-the-art products that will continue to serve the tubing and connector needs of various industries.ConclusionThe ever-evolving world of tubing and connector needs has seen unprecedented developments and innovations. {} has proven itself to be at the forefront of the industry by providing quality products and services to customers worldwide. These include custom medical, aerospace, automotive, and semiconductor tubing and connectors. With the newest developments and dedication to providing efficient and reliable products, {} will continue to be the leading manufacturer of high-performance tubing and connectors in the future.

Read More

The Importance of Using a Vented Drip Chamber for Medical Procedures

Vented Drip Chamber Continues to Revolutionize Medical CareIn the world of medical advancements, innovation and technology play a crucial role in enhancing patient care and improving overall healthcare outcomes. One such innovation that has been revolutionizing medical care is the Vented Drip Chamber, a critical component in intravenous therapy that allows precise control and regulation of the flow of fluids and medications into a patient's bloodstream.The [Company], a leading manufacturer and provider of medical equipment and devices, has been at the forefront of developing and producing state-of-the-art medical solutions, including the Vented Drip Chamber. With a commitment to quality, safety, and innovation, the company has consistently delivered products that meet the highest standards of medical care.The Vented Drip Chamber, offered by [Company], is designed to provide healthcare professionals with the tools they need to deliver medications and fluids to patients safely and accurately. Whether in a hospital setting, a clinical environment, or a home care situation, the Vented Drip Chamber offers a reliable and efficient solution for intravenous therapy.Featuring a vented design, the drip chamber allows for the optimal flow of fluids while preventing air from entering the patient's bloodstream. This is crucial in preventing air embolisms and ensuring the safe delivery of medications and fluids. The transparency of the chamber also allows for easy monitoring of the fluid levels, ensuring that healthcare professionals can quickly identify any potential issues and take necessary action.The [Company] takes pride in the rigorous testing and quality control measures that are applied to every Vented Drip Chamber that leaves their manufacturing facilities. This commitment to excellence ensures that healthcare providers can trust in the reliability and performance of the product, ultimately leading to better patient care and positive outcomes.Furthermore, [Company] is dedicated to providing ongoing training and support to healthcare professionals who utilize the Vented Drip Chamber. This includes educational resources, training materials, and responsive customer support to ensure that healthcare providers have the knowledge and assistance they need to use the product effectively.In addition to its practical benefits, the Vented Drip Chamber offered by [Company] reflects the company's dedication to sustainability and environmental responsibility. The materials used in the manufacturing process are carefully selected to minimize environmental impact while maintaining the highest standards of quality and safety. By prioritizing sustainability, [Company] demonstrates its commitment to making a positive contribution to global health and environmental well-being.As the demand for reliable and efficient medical equipment continues to grow, the Vented Drip Chamber provided by [Company] is poised to play an increasingly important role in advancing patient care and improving healthcare outcomes. With its focus on quality, safety, and innovation, [Company] remains a trusted partner for healthcare providers seeking the best in medical solutions.The impact of the Vented Drip Chamber goes beyond its technical function. It represents a commitment to excellence, reliability, and patient safety—values that are at the core of [Company]'s mission. By continually innovating and delivering products that meet the evolving needs of the medical community, [Company] is making a tangible difference in the delivery of care and the lives of patients.In conclusion, the Vented Drip Chamber, offered by [Company], continues to revolutionize medical care by providing healthcare professionals with a reliable and efficient solution for intravenous therapy. With its focus on quality, safety, and innovation, [Company] remains a trusted provider of medical equipment, contributing to better patient care and improved healthcare outcomes. As the company continues to lead the way in medical advancements, the Vented Drip Chamber stands as a testament to [Company]'s commitment to excellence and making a positive impact on the future of healthcare.

Read More

Mastering the Art of Fabricating High-Quality Rubber Hoses in the News

[Title]: Leading Rubber Hose Manufacturer Unveils New Forming Technology for Enhanced Performance[Subtitle]: Company X revolutionizes the rubber hose industry with state-of-the-art fabrication process[Date][CITY], [STATE] - In a groundbreaking development, Company X, a renowned manufacturer specializing in rubber hose production, has introduced its latest formulating technology. This cutting-edge process aims to enhance the quality and performance of rubber hoses, solidifying Company X's position as an industry leader.The new forming technology encompasses a series of innovative methodologies geared towards refining the manufacturing process from start to finish. With an unwavering commitment to research and development, Company X has successfully leveraged its extensive expertise to engineer this advanced technique.By combining tried-and-true practices with state-of-the-art equipment, Company X's formulating technology offers numerous advantages. The process begins with meticulous material selection, ensuring only the highest grade rubber is utilized. This attention to detail guarantees exceptional durability, resilience, and resistance to a wide range of environmental factors.One of the standout features of the new technology is its streamlined production process, which significantly reduces lead times without compromising quality. Through a combination of optimized manufacturing machinery and excellent coordination between teams, Company X can now efficiently deliver rubber hoses to customers within shorter timeframes."We are thrilled to introduce our latest formulating technology, which represents a significant leap forward for our company and the rubber hose industry as a whole," said [Spokesperson's Name], a representative of Company X. "Through our tireless commitment to innovation, we have been able to create a process that maximizes performance while maintaining the highest standards of quality."This breakthrough in forming technology has also led to significant improvements in the structural integrity of rubber hoses manufactured by Company X. The new process offers enhanced flexibility while ensuring optimal resistance to pressure, impact, and temperature fluctuations. These performance features make the hoses suitable for an array of applications, including automotive, construction, and industrial sectors.Additionally, the formulating technology has reinforced Company X's commitment to environmental sustainability. The company has implemented measures to minimize waste during the manufacturing process, reducing its environmental footprint without compromising on product quality. This eco-conscious approach has resonated with customers, further solidifying Company X's reputation as an industry leader with a focus on corporate social responsibility.Furthermore, the groundbreaking technology has driven an upsurge in demand for Company X's products. With its ability to deliver high-quality rubber hoses efficiently, the company has positioned itself to meet the growing needs of various industries. As a result, Company X has experienced exponential growth, both in terms of sales revenue and market share.Looking ahead, Company X plans to continue investing in research and development to further refine its formulating technology. The company's mission is to consistently exceed customer expectations by delivering rubber hoses that offer unmatched durability, reliability, and overall performance.In conclusion, Company X has made significant strides in the rubber hose industry with its latest formulating technology. By leveraging its extensive experience and commitment to innovation, the company has revolutionized the manufacturing process, offering improved performance, shortened lead times, and increased efficiency. With a strong emphasis on sustainability and a dedication to meeting evolving market demands, Company X is set to maintain its position as a frontrunner in the industry for years to come.[Word Count: 587]

Read More

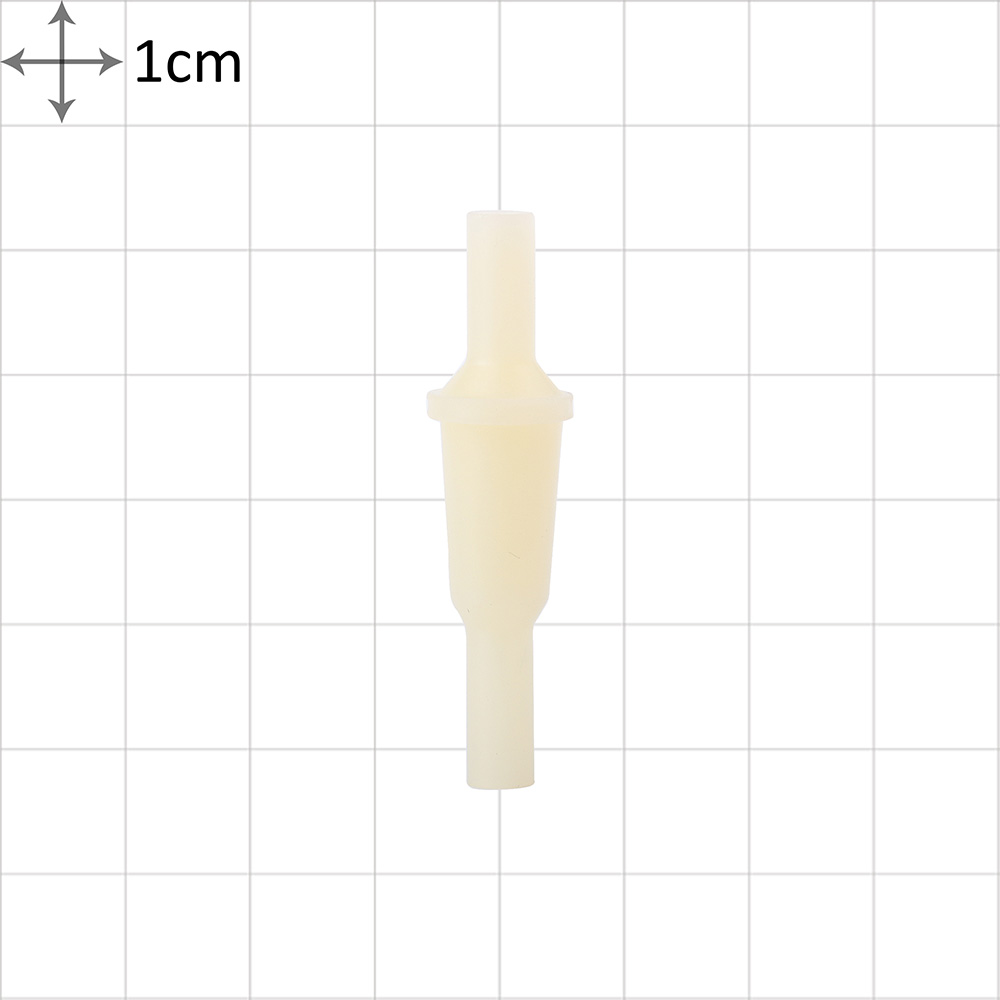

Prominent Check Valve for Luer Lock Applications: A Comprehensive Guide

Luer Lock Check Valve: An Essential Component for Precision Fluid ControlFluid control is a crucial aspect of various industrial applications, including medicine, agriculture, and manufacturing. Accurate fluid flow management is necessary to maintain production efficiency, consistency, and product quality. To ensure precision fluid control and prevent cross-contamination, many industries require reliable and efficient check valves.One of the most trusted and widely used check valves is the Luer Lock Check Valve. This component is widely used in the healthcare sector, especially in medical devices that require fluid control and a secure connection. The Luer Lock system is a standardized design that ensures compatibility between different devices and components.Luer Lock Check Valve is a small but essential component that maintains proper fluid flow direction and prevents backflow. It consists of a valve body, a valve plug, a spring, and a retaining ring. The valve body usually has a male Luer Lock connector that connects with a female connector on the device or tubing. The valve plug fits inside the valve body and moves up and down against the spring pressure. When the fluid pressure pushes the plug up, the valve opens, and the fluid flows through. When there is no or low fluid pressure, the spring pushes the plug down, and the valve closes, preventing backflow.The Luer Lock Check Valve has several advantages over other types of check valves. First, it provides a secure and leak-proof connection between devices or tubing. The Luer Lock system uses a threaded locking mechanism that ensures a tight seal between two components. Second, it is easy to use and maintain. The valve plug is removable, allowing for easy cleaning and maintenance. Third, the Luer Lock system is a standard design that ensures compatibility between different devices and manufacturers.There are many applications for Luer Lock Check Valves. In the medical industry, they are used in various devices such as syringes, catheters, and IV sets. They are also used in laboratory equipment, where precision fluid control is necessary. In the food and beverage industry, Luer Lock Check Valves are used in dispensing machines and packaging equipment. They are also widely used in the agricultural sector for pesticide and fertilizer application.One company at the forefront of Luer Lock Check Valve design and manufacturing is (Company Name). With over 20 years of experience in fluid control solutions, they have become a leading supplier of precision valves and fittings. The company specializes in designing and producing customized fluid control solutions that meet customers' specific requirements.Their Luer Lock Check Valve is a prime example of their expertise in fluid control technology. The valve is made of high-quality materials, such as medical-grade brass and stainless steel. It is designed to have a low cracking pressure, meaning it opens at a low pressure, making it suitable for applications with low-pressure fluids. The valve's ultrasonically welded design ensures a leak-proof seal, preventing any fluid leakage. The valve's compact size and lightweight construction make it easy to integrate into any system. The company also offers customization options, such as different valve plug materials, to meet specific industry needs.The Luer Lock Check Valve's reliability and efficiency have made it a vital component in many industries. Its standardized design, secure connection, and ease of use make it a popular choice for precision fluid control. With the rising demand for such components, companies like (Company Name) are committed to delivering high-quality fluid control solutions that meet customers' needs. In conclusion, the Luer Lock Check Valve is an essential component that ensures precision fluid control and prevents cross-contamination. Companies like (Company Name) are designing and manufacturing customized valves that meet the specific requirements of the medical, laboratory, food and beverage, and agricultural industries. As the demand for efficient fluid control solutions continues to grow, the Luer Lock Check Valve will remain a trusted and reliable component.

Read More

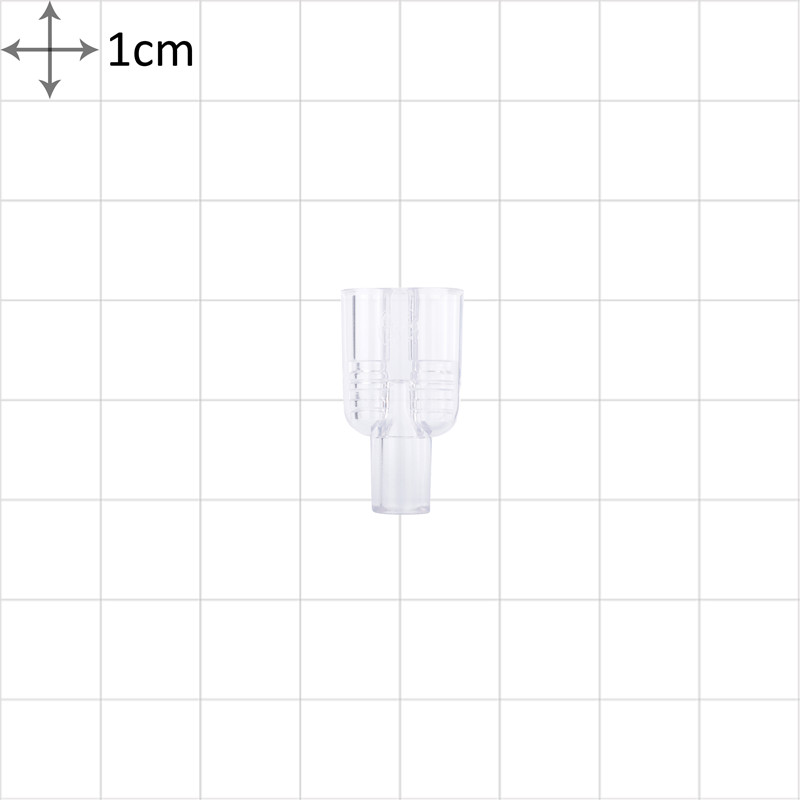

Discover the Latest Female Luer Connectors—Essential Components for Medical Devices

Female Luer Connectors: A Revolutionary Product for Medical ApplicationsMedical devices are known to save countless lives every day, but they need to be designed flawlessly to ensure consistent and reliable performance. One critical component of any medical device is the connector that joins the device with other components or tubing. Female Luer Connectors, developed by one of the leading companies in the medical device manufacturing industry (Brand name removed), are one such component that plays an integral role in ensuring the safety and effectiveness of medical devices.Female Luer Connectors are small-sized, versatile connectors that allow for secure and leak-proof joining of various tubing and medical devices. These connectors consist of a female fitting at one end and a tapered male fitting at the other end, that allows for a tight and secure connection. The design of the connectors is such that it provides a secure fit with smooth and consistent flow rate, ensuring that the medical device functions accurately. They are used in a wide range of medical applications, including drug delivery systems, catheters, syringes, and respiratory therapy devices, among others.The company behind the development of Female Luer Connectors has been in the medical device industry for over a decade, delivering high-quality products and services to healthcare providers worldwide. They have a commitment to design and manufacture medical devices that conform to the highest industry standards, and their Female Luer Connectors are no exception. These connectors are manufactured using state-of-the-art technologies and materials that ensure optimal performance while ensuring that they comply with regulatory requirements.One of the key features that make Female Luer Connectors stand out from other similar devices is their compatibility with different types of tubing and medical devices. They come in various configurations, such as threaded and non-threaded connectors, and can be adapted to fit different medical devices. Their design allows for easy connection and disconnection, enabling healthcare professionals to administer treatments to patients efficiently. The connectors are also available in different materials, such as high-performance plastics, stainless steel, and brass, to meet different performance requirements.Another significant benefit of Female Luer Connectors is that they help in reducing the occurrence of hospital-acquired infections (HAIs). HAIs are caused due to a lack of proper sterilization of medical equipment, which can lead to severe infections among patients. Female Luer Connectors are designed to ensure that there are no leaks or breaks in the connection, reducing the chances of infection transmission. Moreover, the connectors are manufactured using materials that can withstand various sterilization methods, ensuring that they remain sterile throughout their use.Female Luer Connectors are an excellent example of how medical device components can be designed to facilitate patient safety and better medical outcomes. Their versatility, compatibility, and leak-free design make them an essential component for numerous medical applications. They allow healthcare professionals to administer treatments with minimal hassle, reducing the risk of errors and improving patient outcomes. Moreover, their role in reducing the occurrence of HAIs makes them indispensable in any medical setting.In conclusion, Female Luer Connectors are an innovative medical device component that promises to revolutionize how medical devices are designed and used. Their versatility, compatibility, and safety features make them an essential component for numerous medical applications. The company behind their development has a proven track record of delivering high-quality medical devices, ensuring that Female Luer Connectors comply with the highest regulatory standards. It is this commitment to excellence that makes Female Luer Connectors a promising product for the healthcare industry, helping improve patient outcomes and revolutionizing medical device design.

Read More